PRODUCTS

Amer-Sil has been developing cutting-edge products for industrial batteries for over 50 years.

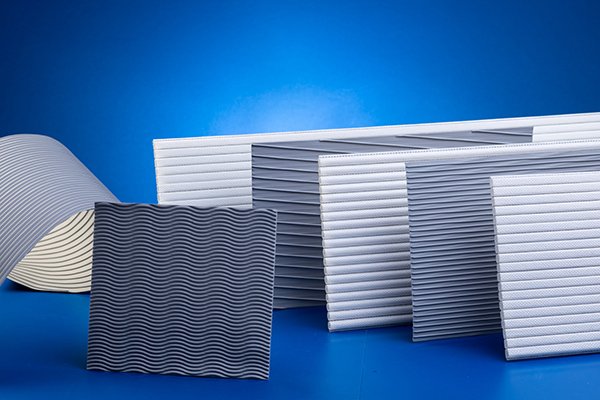

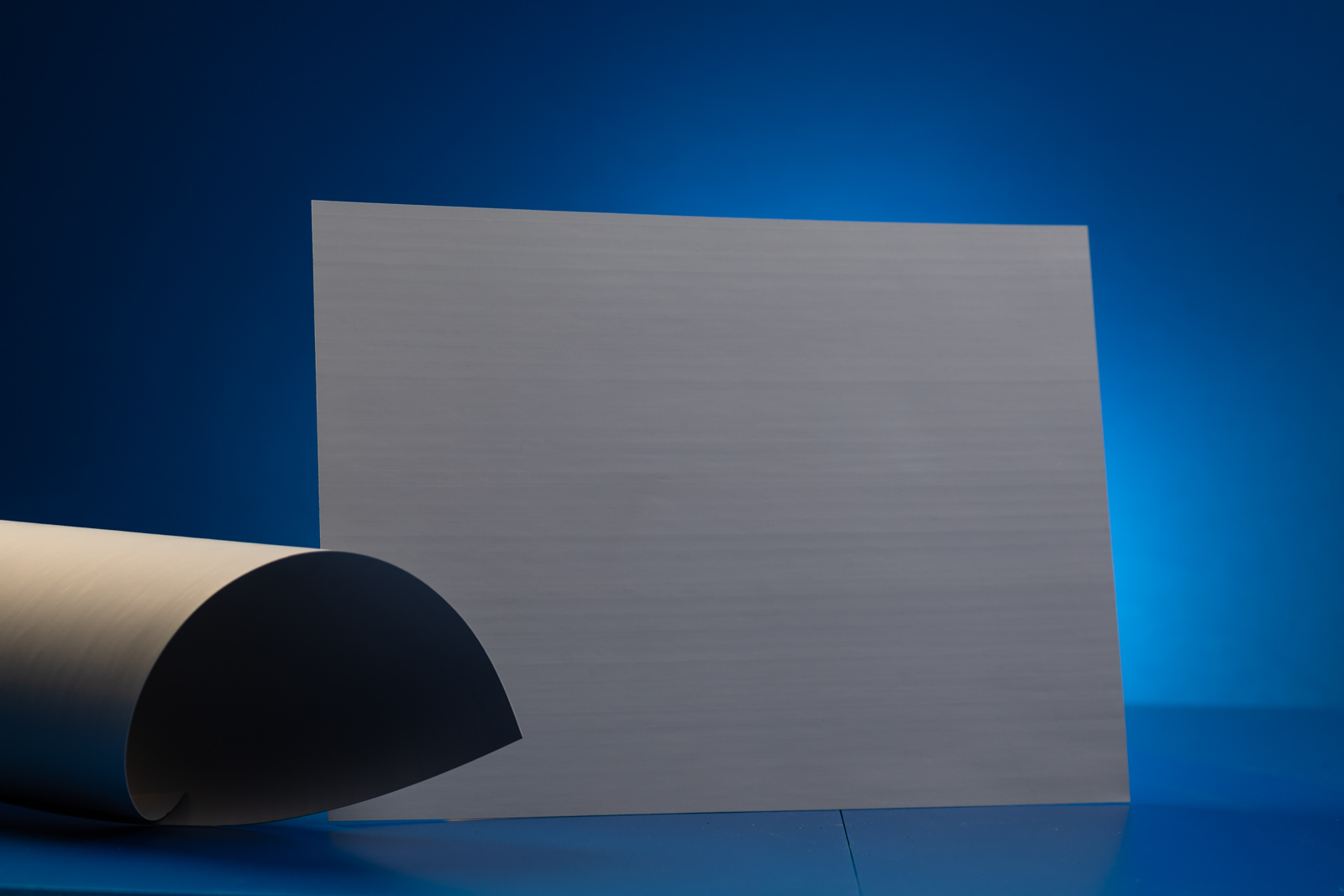

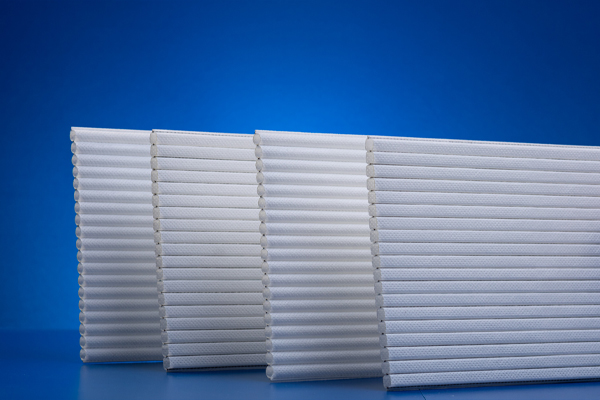

We are the only global supplier proposing BOTH, separators AND gauntlets, offering a unique portfolio for the increasing demand of lead-acid batteries. We provide a broad choice of products meeting all needs of our customers.

For renewable energy storage applications using Redox Flow Batteries, Amer-Sil offers small pore separators which can be successfully adopted in various types – vanadium, zinc bromine, all-iron.

Please don’t hesitate to contact us for customized solutions.