Industrial Lead Acid Batteries

SEPARATORS

For more than 50 years now, we have been offering different separator solutions to match any industrial battery application. Our separators are suitable for both tubular and flat plate technologies. They are obtained via the extrusion and calendering of PVC-silica compound. No mineral oil is used in the extrusion process.

We are able to draw on several decades of successful collaboration with most of the top-quality battery makers around the world.

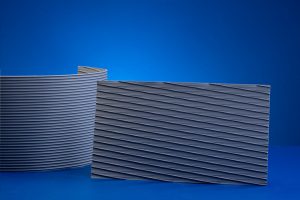

We recently developed a flexible and non-brittle PVC-silica separator. This new separator provides for excellent battery performance while also making battery assembly much easier and trouble-free.

Please don’t hesitate to contact us for customized solutions.

We offer different separator solutions for the following applications:

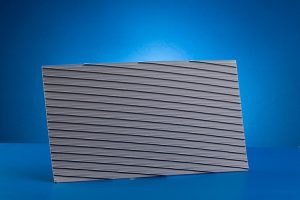

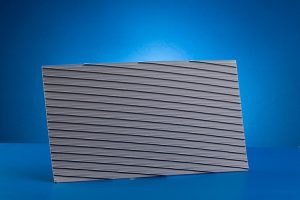

TRACTION – MOTIVE POWER represents one of the most challenging scenarios for a battery and its components, due to the high mechanical and electrical requirements involved.

To optimize battery performance, we are in the final stages of developing the AS-Motra separator, which represents an optimal solution for your needs.

|

FEATURES AND BENEFITS • High volume porosity, 68% • Very low level of acid displacement • Very low electrical resistance (ER) • Wettability • Easy handling • Diverse pattern portfolio • Excellent oxidation resistance, despite absence of mineral oil • Our production lines allow low-volume series without any strict minimum order quantities

|

|

• Available in thickness ranging from 1 mm to 4 mm We also offer customized solutions to best fit your needs and we will be happy to discuss your individual specifications. |

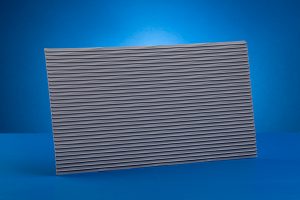

Stationary – Reserve power – Standby

For stationary reserve power standby applications, our AS-Endura separator represents an optimal solution for your needs.

|

FEATURES AND BENEFITS • 72% volume porosity • Very low level of acid displacement • Very low electrical resistance (ER) • Easy handling • Wettability • Excellent oxidation resistance, despite absence of phenol-formaldehyde resin and mineral oil • Compatible with phosphoric acid • Our production lines allow low-volume series without any strict minimum order quantities

|

|

• Available in thickness ranging from 0.6 mm to 4.5 mm We also offer customized solutions to best fit your needs and we will be happy to discuss your individual specifications. |

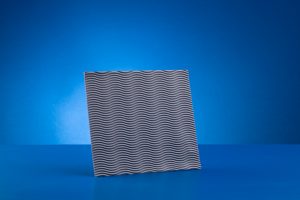

GEL monobloc

Our AS-HyperGel separator has been a market trailblazer for many years now in the field of high-quality gel monobloc applications.

|

CORRUGATED SEPARATORS • High-volume porosity ranging from 73% to close to 80% • Excellent oxidation resistance, despite absence of phenol-formaldehyde resin and mineral oil • Compatible with phosphoric acid |

|

We also offer customized solutions to best fit your needs and we will be happy to discuss your individual specifications. |

We offer different separator solutions for the following applications:

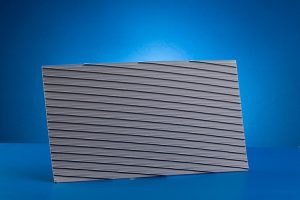

TRACTION – MOTIVE POWER represents one of the most challenging scenarios for a battery and its components, due to the high mechanical and electrical requirements involved.

To optimize battery performance, we are in the final stages of developing the AS-Motra separator, which represents an optimal solution for your needs.

|

FEATURES AND BENEFITS • High volume porosity, 68% • Very low level of acid displacement • Very low electrical resistance (ER) • Wettability • Easy handling • Diverse pattern portfolio • Excellent oxidation resistance, despite absence of mineral oil • Our production lines allow low-volume series without any strict minimum order quantities

• Available in thickness ranging from 1 mm to 4 mm We also offer customized solutions to best fit your needs and we will be happy to discuss your individual specifications. |

|

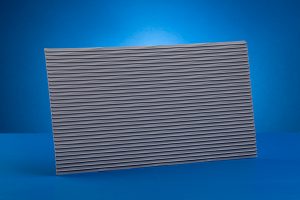

Stationary – Reserve power – Standby

For stationary reserve power standby applications, our AS-Endura separator represents an optimal solution for your needs.

|

FEATURES AND BENEFITS • 72% volume porosity • Very low level of acid displacement • Very low electrical resistance (ER) • Easy handling • Wettability • Excellent oxidation resistance, despite absence of phenol-formaldehyde resin and mineral oil • Compatible with phosphoric acid • Our production lines allow low-volume series without any strict minimum order quantities

• Available in thickness ranging from 0.6 mm to 4.5 mm We also offer customized solutions to best fit your needs and we will be happy to discuss your individual specifications.

|

|

GEL monobloc

Our AS-HyperGel separator has been a market trailblazer for many years now in the field of high-quality gel monobloc applications.

|

CORRUGATED SEPARATORS • High-volume porosity ranging from 73% to close to 80% • Excellent oxidation resistance, despite absence of phenol-formaldehyde resin and mineral oil • Compatible with phosphoric acid

We also offer customized solutions to best fit your needs and we will be happy to discuss your individual specifications. |

|